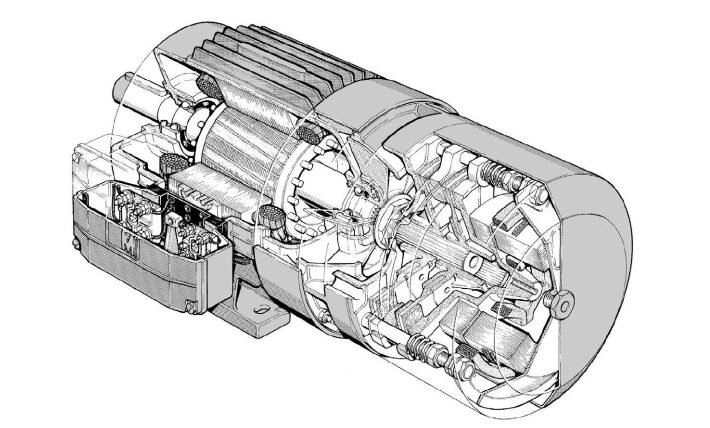

Some applications of a brake motor, such as in lifting systems, require an available braking torque of at least twice the motor’s rated torque.

All MGM brake motors of the BAX series with an AC brake and a single brake disc offer this feature.

BAX motors can also be supplied with a double brake disc (BAXF version), but our technical department, along with our sales department, generally advises against this solution.

Let’s take a look at the main disadvantages of this configuration:

- To ensure that the brake releases correctly the air gap (i.e., the distance between the moving armature and the magnet) must be twice that of the corresponding single-disc version. This is because the space needed for each disc to avoid dangerous rubbing between the brake disc and friction surfaces must remain the same as in the single-disc version. Since there are two discs, the total space—and therefore the air gap—doubles.

A larger air gap results in a higher need for maintenance and greater electrical and mechanical stress on the entire brake assembly. - The weakest part of the brake disc is the friction lining. Normally the worst-case scenario is the total or partial detachment of the friction lining from the brake disc. With a double-disc brake, the number of friction linings is doubled compared to a single-disc brake and so is the likelihood of this unfortunate event.

It should also be noted that in the event of damage to one of the brake discs, the other loses braking capacity as well due to the decompression of the springs.

Therefore, the double-disc solution is not inherently safer than the single-disc one. - The maintenance of a brake motor with a double brake disc, in addition to being more frequent, is also more complex than that of a single-disc brake motor.

The use of brake motors with double brake discs should therefore only be considered when the required braking torque is approximately 4 to 5 times higher than the motor’s rated torque and only after carefully evaluating the possible drawbacks to the rest of the machine’s drive system.

Mon - Fri 8:00 - 17:00

Mon - Fri 8:00 - 17:00