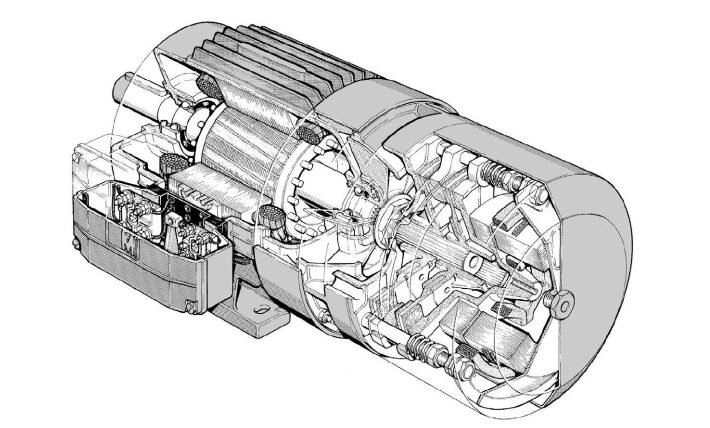

The choice of the protection class for a motor must be appropriate to the conditions of the environment in which it will operate. The required protection class for the proper functioning of the motor will, for example, be different if the motor is applied inside a factory, outdoors, or in the middle of a desert. According to the EN 60034-5 standard, the protection class is designated by a code consisting of the letters IP followed by two digits (IP First digit Second digit).

The first digit indicates the degree of protection provided by the motor’s enclosure against contact with live or moving parts or against the penetration of external solid bodies. The second digit indicates the degree of protection of the motor’s enclosure against harmful effects due to the penetration of liquids.

Going into a bit more detail, we have:

First digit

0 No protection.

1 Protected against the penetration of solid bodies larger than 50 mm (for example, protection against accidental contact with the hand).

2 Protected against the penetration of solid bodies larger than 12 mm.

3 Protected against the penetration of solid bodies larger than 2.5 mm.

4 Protected against the penetration of solid bodies larger than 1 mm.

5 Protected against the penetration of dust. Dust penetration is not completely prevented, but it must not impair the proper functioning of the machine.

6 Completely protected against dust.

Second digit

0 No protection.

1 Vertical drops of water must not cause harmful effects on the machine.

2 Vertical drops of water must not cause harmful effects on the machine when the machine is tilted up to 15° from its normal position.

3 Rainwater falling at an angle of up to 60° must not cause harmful effects on the machine.

4 Water splashes from any direction must not cause harmful effects on the machine.

5 Water jets from any direction must not cause harmful effects on the machine.

6 Water waves must not cause harmful effects on the machine.

7 Immersion in water under specified pressure and duration conditions must not cause harmful amounts of water to enter the machine.

8 Permanent immersion in water under conditions specified by the manufacturer must not have harmful effects.

Let’s now look at some common practical cases.

For use in a normal industrial environment, an IP54 protection class is sufficient. For motors intended to operate outdoors or in contact with water, the recommended protection class is IP55, or even better, IP56. However, to ensure a long service life, it is advisable to adopt additional protections, such as the use of appropriate rain covers.

If the motor is to be installed in a very dusty industrial environment, or near desert areas or beaches, the most appropriate protection class would be IP56 or IP66.

Naturally, it is important to check that the dust mixture is not explosive.

During installation, ensure the proper tightening of cable gland entries, and when possible, arrange for the cable to enter with a curvature from the bottom to the top.

For vertical mounting with the control side facing downward, it is always necessary to specify this at the time of purchase and request that the motor manufacturer apply the rain cover or other devices.

Mon - Fri 8:00 - 17:00

Mon - Fri 8:00 - 17:00